The Grip-M is flex coupling, has two thick sealing lips which allow for pipe expansion and contraction. This type of coupling not only connects pipes, it simultaneously compensates the axial movement, giving a significant added value to the coupling.

Multi-function Pipe Coupling is suitable for the pipes with outside diameter range of 26.9~2032mm.

Suitable for pipes material: Carbon steel, stainless steel, copper, cunifer, cast and ductile iron, GRP, asbestos cement, HDPE, MDPE,, PVC, uPVC, ABS and other material.

Working pressure up to 40bar.

Multi-function Pipe Connector (GRIP-M) has the advantage of without axial constraint and its structure can finish expansion and shrinkage, which is suitable for shipbuilding, water and waster water treatment plant and industrial pipes, etc. No matter pumping pipe or belt pressing pipe, it can be installed safely and quickly.

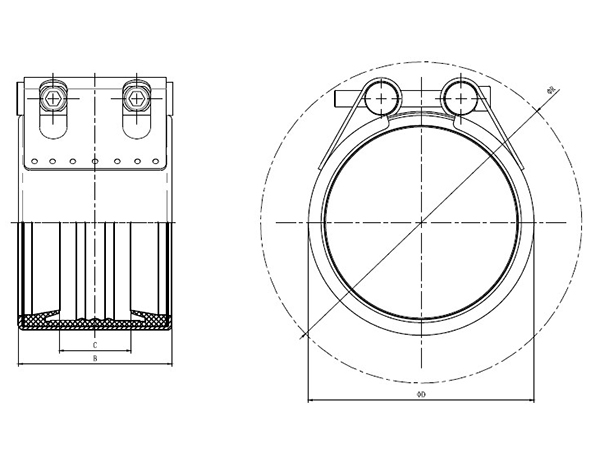

GRIP-M Technical parameters

| Pipe outside diameter |

Clamping range |

Working pressure |

Product O.D. |

Width |

Distance between sealing slips |

Setting gap between pipe ends |

Torque rate |

Bolt |

| O.D. |

Min-Max |

|

|

Φ D |

B |

C |

without strip insert |

with strip insert (Max) |

| (mm) |

(In.) |

(mm) |

(bar) |

(bar) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(Nm) |

M |

| 26.9 |

1.059 |

26-28 |

25 |

40 |

38.9 |

61 |

26 |

5-8 |

10 |

5 |

M6×2 |

| 30 |

1.181 |

29-31 |

25 |

40 |

42 |

61 |

26 |

5-8 |

10 |

5 |

| 33.7 |

1.327 |

32-35 |

25 |

40 |

45.7 |

61 |

26 |

5-8 |

10 |

5 |

| 38 |

1.496 |

37-39 |

25 |

40 |

52 |

61 |

26 |

5-8 |

10 |

7.5 |

M8×2 |

| 42.4 |

1.669 |

41-43 |

25 |

40 |

56.4 |

61 |

26 |

5-8 |

10 |

7.5 |

| 44.5 |

1.752 |

44-45 |

25 |

40 |

58.5 |

61 |

26 |

5-8 |

10 |

7.5 |

| 48.3 |

1.902 |

47-50 |

25 |

40 |

62.3 |

61 |

26 |

5-8 |

10 |

7.5 |

| 54 |

2.126 |

52-56 |

20 |

35 |

70 |

76 |

37 |

5~10 |

15 |

10 |

| 57 |

2.244 |

55-59 |

20 |

35 |

73 |

76 |

37 |

5~10 |

15 |

10 |

| 60.3 |

2.374 |

59-62 |

20 |

35 |

76.3 |

76 |

37 |

5~10 |

15 |

10 |

| 66.6 |

2.622 |

64-68 |

20 |

40 |

82.6 |

95 |

37 |

5~10 |

25 |

20 |

| 70 |

2.756 |

68-71 |

20 |

40 |

86 |

95 |

41 |

5~10 |

25 |

20 |

| 73 |

2.874 |

71-75 |

20 |

40 |

89 |

95 |

41 |

5~10 |

25 |

20 |

| 76.1 |

2.996 |

74-78 |

20 |

40 |

92.1 |

95 |

41 |

5~10 |

25 |

20 |

| 79.5 |

3.130 |

78-80 |

20 |

40 |

95.5 |

95 |

41 |

5~10 |

25 |

20 |

| 84 |

3.307 |

82-86 |

20 |

40 |

100 |

95 |

41 |

5~10 |

25 |

20 |

| 88.9 |

3.500 |

87-91 |

20 |

40 |

104.9 |

95 |

41 |

5~10 |

25 |

20 |

| 100.6 |

3.961 |

99-103 |

18 |

35 |

118.6 |

95 |

41 |

5~10 |

25 |

20 |

| 101.6 |

4.000 |

100-104 |

18 |

35 |

119.6 |

95 |

41 |

5~10 |

25 |

20 |

| 104 |

4.094 |

102-106 |

18 |

35 |

122 |

95 |

41 |

5~10 |

25 |

20 |

| 108 |

4.252 |

103-107 |

18 |

35 |

126 |

95 |

41 |

5~10 |

25 |

20 |

| 114.3 |

4.500 |

113-116 |

18 |

35 |

132.3 |

95 |

41 |

5~10 |

25 |

20 |

| 127 |

5.000 |

126-128 |

18 |

40 |

149 |

110 |

54 |

5~10 |

35 |

25 |

M10×2 |

| 129 |

5.079 |

128-130 |

18 |

40 |

151 |

110 |

54 |

5~10 |

35 |

25 |

| 130.2 |

5.126 |

129-132 |

18 |

40 |

152.2 |

110 |

54 |

5~10 |

35 |

25 |

| 133 |

5.236 |

131-135 |

18 |

40 |

155 |

110 |

54 |

5~10 |

35 |

25 |

| 139.7 |

5.500 |

138-142 |

18 |

40 |

161.7 |

110 |

54 |

5~10 |

35 |

25 |

| 141.3 |

5.563 |

140-143 |

18 |

40 |

163.3 |

110 |

54 |

5~10 |

35 |

25 |

| 154 |

6.063 |

153-156 |

18 |

35 |

176 |

110 |

54 |

5~10 |

35 |

25 |

| 159 |

6.260 |

158-161 |

18 |

35 |

181 |

110 |

54 |

5~10 |

35 |

25 |

| 168.3 |

6.626 |

167-170 |

18 |

35 |

190.3 |

110 |

54 |

5~10 |

35 |

25 |

| 180 |

7.087 |

166-171 |

16 |

30 |

202 |

142 |

75 |

10~25 |

40 |

50 |

M12×2 |

| 200 |

7.874 |

198-202 |

16 |

30 |

222 |

142 |

75 |

10~25 |

40 |

50 |

| 219.1 |

8.626 |

216-222 |

16 |

30 |

249.1 |

142 |

75 |

10~25 |

40 |

60 |

| 250 |

9.843 |

247-253 |

16 |

25 |

280 |

142 |

75 |

10~25 |

40 |

60 |

| 267 |

10.512 |

264-270 |

16 |

25 |

297 |

142 |

75 |

10~25 |

40 |

60 |

| 273 |

10.748 |

270-276 |

16 |

25 |

303 |

142 |

75 |

10~25 |

40 |

60 |

| 304 |

11.969 |

301-307 |

10 |

20 |

334 |

142 |

75 |

10~25 |

40 |

80 |

| 323.9 |

12.752 |

321-327 |

10 |

20 |

353.9 |

142 |

75 |

10~25 |

40 |

80 |

| 355.6 |

14.000 |

353-358 |

8.5 |

16 |

385.6 |

142 |

75 |

10~25 |

40 |

80 |

| 377 |

14.843 |

375-379 |

8.5 |

16 |

407.0 |

142 |

75 |

10~25 |

40 |

80 |

| 406.4 |

16.000 |

404-409 |

7.5 |

16 |

436.0 |

142 |

75 |

10~25 |

40 |

80 |

| 457.2 |

18.000 |

454-460 |

6.5 |

12 |

487.0 |

142 |

75 |

10~25 |

40 |

80 |

| 508 |

20.000 |

505-511 |

6 |

10 |

538.0 |

142 |

75 |

10~25 |

40 |

120 |

M16×2 |

| 558.8 |

22.000 |

556-562 |

5.5 |

10 |

588.8 |

142 |

75 |

10~25 |

40 |

160 |

| 609.6 |

24.000 |

606-613 |

5 |

10 |

639.6 |

142 |

75 |

10~25 |

40 |

160 |

| 711.2 |

28.000 |

708-715 |

4 |

5 |

741.2 |

142 |

75 |

10~25 |

40 |

160 |

| 762 |

30.000 |

758-766 |

4 |

5 |

792.0 |

142 |

75 |

10~25 |

40 |

160 |

| 812.8 |

32.000 |

809-817 |

4 |

5 |

842.8 |

142 |

75 |

10~25 |

40 |

200 |

| 914.4 |

36.000 |

910-918 |

4 |

5 |

944.4 |

142 |

75 |

10~25 |

40 |

200 |

| 1016 |

40.000 |

1012-1020 |

4 |

5 |

1046.0 |

142 |

75 |

10~25 |

40 |

200 |

| 1117.6 |

44.000 |

1114-1122 |

3.5 |

5 |

1147.6 |

142 |

75 |

10~25 |

40 |

200 |

| 1219.2 |

48.000 |

1215-1224 |

3.5 |

5 |

1249.2 |

142 |

75 |

10~25 |

40 |

200 |

| 1320.8 |

52.000 |

1316-1325 |

3 |

5 |

1350.8 |

142 |

75 |

10~25 |

40 |

240 |

| 1422.4 |

56.000 |

1418-1427 |

3 |

5 |

1452.4 |

142 |

75 |

10~25 |

40 |

240 |

| 1524 |

60.000 |

1519-1529 |

2.5 |

5 |

1554 |

142 |

75 |

10~25 |

40 |

240 |

| 1600 |

62.992 |

1595-1605 |

2.5 |

5 |

1630 |

142 |

75 |

10~25 |

40 |

240 |

| 1625.6 |

64.000 |

1621-1631 |

2.5 |

5 |

1655.6 |

142 |

75 |

10~25 |

40 |

240 |

| 1727.2 |

68.000 |

1722-1732 |

2.5 |

5 |

1757.2 |

142 |

75 |

10~25 |

40 |

240 |

| 1828.8 |

72.000 |

1824-1834 |

2 |

5 |

1858.8 |

142 |

75 |

10~25 |

40 |

240 |

| 1930.4 |

76.000 |

1925-1936 |

2 |

5 |

1960.4 |

142 |

75 |

10~25 |

40 |

240 |

| 2032 |

80.000 |

2027-2037 |

2 |

5 |

2062 |

142 |

75 |

10~25 |

40 |

240 |

GRIP-M Material Selection

| Material Components |

V1 |

V2 |

V3 |

V4 |

V5 |

V6 |

| Casing |

AISI 304 |

AISI 316L |

AISI 316TI |

AISI 316L |

AISI 316TI |

|

| Bolts |

AISI 304 |

AISI 316L |

AISI 316L |

AISI 304 |

AISI 304 |

|

| Bars |

AISI 304 |

AISI 316L |

AISI 316L |

AISI 304 |

AISI 304 |

|

| Anchoring ring |

|

|

|

|

|

|

| Strip insert (optional) |

AISI 301 |

AISI 301 |

AISI 301 |

AISI 301 |

AISI 301 |

|

Material of rubber gasket

| Material of seal |

Media |

Temperature range |

| EPDM |

All quality of waters,waste water, air, solids and chemical products |

-30℃ up to+120℃ |

| NBR |

Water,gas, oil, fuel and other hydrocanbons |

-30℃upto+120℃ |

| MVQ |

High temperature liquid, oxygen, ozone, water and so on |

-70℃ up to+260℃ |

| FPM/FKM |

Ozone, oxygen, acids,gas, oil and fuel (only with strip insert) |

95℃up to+300℃ |

Basic Features:

Excellent general performance: it is suitable for metallic conduit and non-metallic conduit. And it requires nothing special on media inside the pipe, pipe thickness and end face.

Wide range of application: it not only has good using effect on standard pipes, but also is able to durably keep pressure bearing and leakage-proof of the pipes with axial displacement, angular deviation and inconsistent external diameter at the same time.

Flexible and convenient operation: the product is light in weight, covers small room and can be installed with simple tools. At the same time, with rational structure and layout, it is easy to be dismantled in a short time. And it is of high reuse rate and is easy to be maintained.

Reliable material quality that guarantees safety: dedicate structural design and good fireproofing material quality guarantee the safety when it is installed in fire forbidden and anti-explosion regions.