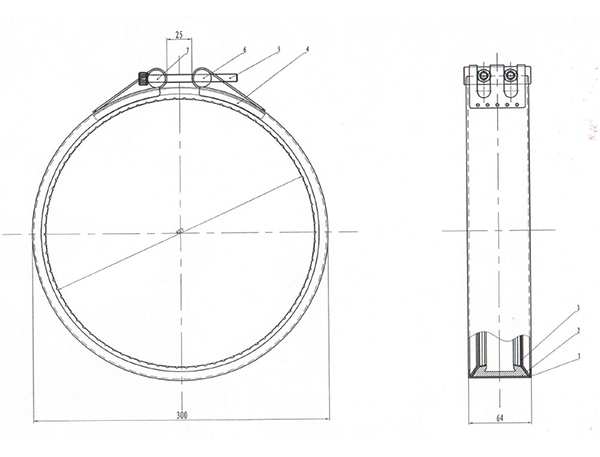

High definition Metal Grip Coupling - Customized narrow coupling – Grip

Customized narrow coupling.

GRIP-GS is narrow type of GRIP-G. Have the same performance of GRIP-G.

It’s suitable for narrow space and applications for low pressure stages of up to 16bar.

Suitable for pipes O.D φ76.1mm—377mm.

Suitable for pipes material: Carbon steel, stainless steel, copper, cunifer, cast and ductile iron, GRP, asbestos cement, HDPE, MDPE, PVC, CPVC, ABS and other material.

Application:

Industrial sector’s service and control lines.

Plant engineering

Process technology.

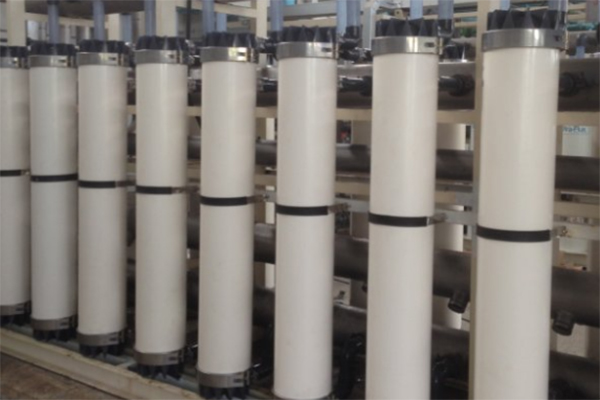

In the module of a water treatment plant

GRIP-GS Technical parameters

GRIP-GS Material Selection

| Material / Components | V1 | V2 | V3 | V4 | V5 | V6 |

| Casing | AISI 304 | AISI 316L | AISI 316TI | AISI 316L | AISI 316TI | |

| Bolts | AISI 304 | AISI 316L | AISI 316L | AISI 304 | AISI 304 | |

| Bars | AISI 304 | AISI 316L | AISI 316L | AISI 304 | AISI 304 | |

| Anchoring ring | AISI 301 | AISI 301 | AISI 301 | AISI 301 | AISI 301 | |

| Strip insert (optional) | AISI 301 | AISI 301 | AISI 301 | AISI 301 | AISI 301 |

Material of rubber gasket

| Material of seal | Media | Temperature range |

| EPDM | All quality of waters,waste water, air, solids and chemical products | -30℃ up to+120℃ |

| NBR | Water,gas, oil, fuel and other hydrocanbons | -30℃upto+120℃ |

| MVQ | High temperature liquid, oxygen, ozone, water and so on | -70℃ up to+260℃ |

| FPM/FKM | Ozone, oxygen, acids,gas, oil and fuel (only with strip insert) | 95℃up to+300℃ |

Benefits of GRIP Couplings

1. Universal use

Compatible with any traditional jointing system

Joins pipes of the same or dissimilar materials

Quick and simple repairs of damaged pipes without service interruptions

2.Reliable

Stress-free, flexible pipe joint

Compensates axial movement and angular deflection

Pressure-resistant and leak-proof even with inaccurate pipe assembly

3.Easy handling

Detachable and reusable

Maintenance free and trouble free

No time-consuming alignment and fitting work

Easy installation technology

4.Durable

Progressive sealing effect

Progressive anchoring effect

Corrosion resistant and temperature resistant

Good resistant to chemicals

Long service time

5.Space-saving

Compact design for space-saving installation of pipes

Light weight

Needs little space

6.Fast and Safe

Easy installation, no fire or explosion hazard during installation

No cost for protective measures

Absorbs vibration /oscillations