Factory making Leaking Ss Pipe Joint - Double Lock Pipe Clamp (Pipe repair with a 2 lock active sealing system coupling) – Grip

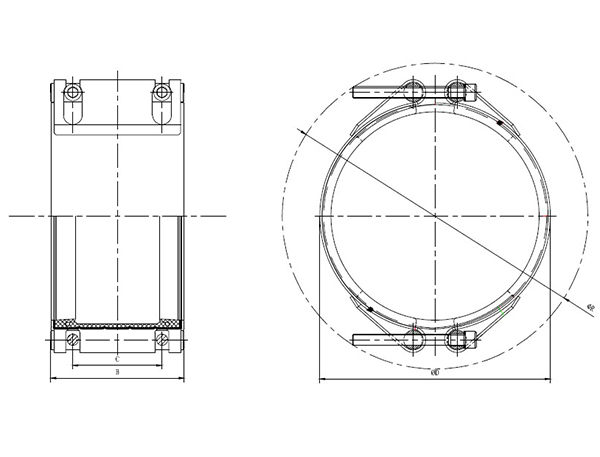

Double Lock Pipe Clamp (Pipe repair with a 2 lock active sealing system coupling)

The Grip-D is two-piece type repair clamp, can be fitted to exiting pipes in situ, without any need to remove and relay the pipes. This makes it the ideal solution for permanent repairs of pipe joints, cracks etc.

It suit for large pipes, two-piece type repair clamp can repair pipe without large installation space.

Suitable for pipes O.D φ180-φ2032mm

Suitable for pipes material: Carbon steel, stainless steel, copper, cunifer, cast and ductile iron, GRP, asbestos cement, HDPE, MDPE,, PVC, uPVC, ABS and other material.

Working pressure up to 30bar.

The advantage of GRIP-D repair clamps is that is can befitted to existing pipes in situation, without any need to remove and replacing pipes, GRIP-R pipe repair clamp can repair the pipes that are ageing and corrosive and pipe wall has holes or cracks. When installing it, it only needs pipe clamp to wrap the leakage part and tighten the bolt. Then the installation is finished ideally and reliably.

Outside diameter of GRIP-D double lock Pipe repair clamp is from 180 to 2032mm.

GRIP-D Technical parameters

GRIP-D Material Selection

| Material / Components | V1 | V2 | V3 | V4 | V5 | V6 |

| Casing | AISI 304 | AISI 316L | AISI 316L | AISI 316TI | AISI 304 | |

| Bolts | AISI 304 | AISI 316L | AISI 304 | AISI 304 | AISI 4135 | |

| Bars | AISI 304 | AISI 316L | AISI 304 | AISI 304 | AISI 4135 | |

| Anchoring ring | ||||||

| Strip insert (optional) | AISI 301 | AISI 301 | AISI 301 | AISI 301 | AISI 301 |

Material of rubber gasket

| Material of seal | Media | Temperature range |

| EPDM | All quality of waters,waste water, air, solids and chemical products | -30℃ up to+120℃ |

| NBR | Water,gas, oil, fuel and other hydrocanbons | -30℃upto+120℃ |

| MVQ | High temperature liquid, oxygen, ozone, water and so on | -70℃ up to+260℃ |

| FPM/FKM | Ozone, oxygen, acids,gas, oil and fuel (only with strip insert) | 95℃up to+300℃ |