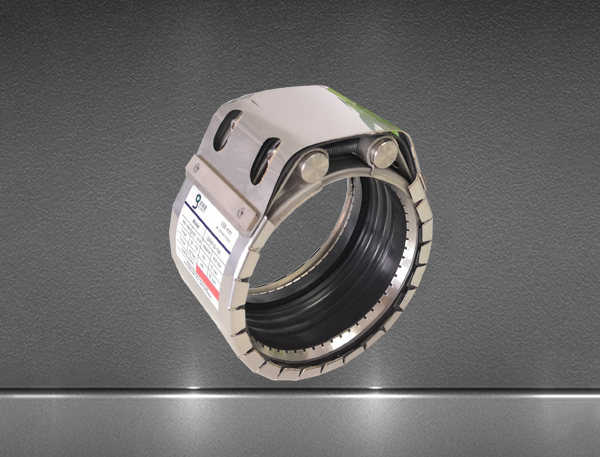

The Grip-GF combines with functional design with the latest technologies. The GRIP-GF is based on the proven coupling technology, which has been developed for the shipbuilding industry, also is successfully used for tunneling, fire hose applications etc. In the event of a fire, GRIP-GF coupling protectively enclosing the coupling. During this process, the coupling retains its full operational capability without any damage.

Suitable for pipes O.D φ26.9-φ273mm

Suitable for pipes material: Carbon steel, stainless steel, copper, cunifer, GRE, and other material

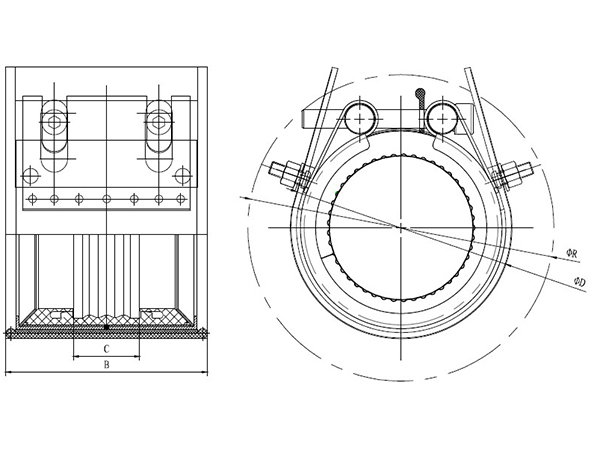

GRIP-GF Technical parameters

| Pipe outside diameter |

Clamping range |

Working pressure |

Product O.D. |

Width |

Distance between sealing slips |

Setting gap between pipe ends |

Torque rate |

Bolt |

| O.D. |

Min-Max |

|

|

Φ D |

B |

C |

without strip insert |

with strip insert (Max) |

| (mm) |

(In.) |

(mm) |

(bar) |

(bar) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(Nm) |

M |

| 26.9 |

1.059 |

26-28 |

18 |

46 |

55 |

61 |

19 |

5~8 |

10 |

8 |

M6×2 |

| 30 |

1.181 |

29-31 |

18 |

46 |

58 |

61 |

19 |

5~8 |

10 |

8 |

| 33.7 |

1.327 |

32-35 |

18 |

40 |

62 |

61 |

19 |

5~8 |

10 |

8 |

| 38 |

1.496 |

37-39 |

18 |

35 |

69 |

61 |

26 |

5~8 |

10 |

10 |

M8×2 |

| 42.4 |

1.669 |

41-43 |

18 |

32 |

73.3 |

61 |

26 |

5~8 |

10 |

10 |

| 44.5 |

1.752 |

44-45 |

18 |

32 |

75.4 |

61 |

26 |

5~8 |

10 |

10 |

| 48.3 |

1.902 |

47-49 |

18 |

32 |

79.2 |

61 |

26 |

5~8 |

10 |

10 |

| 54 |

2.126 |

53-55 |

18 |

32 |

85 |

76 |

37 |

5~10 |

15 |

10 |

| 57 |

2.244 |

56-58 |

18 |

32 |

88 |

76 |

37 |

5~10 |

15 |

10 |

| 60.3 |

2.374 |

59-61 |

18 |

32 |

91.2 |

76 |

37 |

5~10 |

15 |

10 |

| 66.6 |

2.622 |

64-68 |

18 |

32 |

100.7 |

95 |

37 |

5~10 |

25 |

20 |

M8×2 |

| 70 |

2.756 |

68-71 |

18 |

32 |

104 |

95 |

41 |

5~10 |

25 |

20 |

| 73 |

2.874 |

72-74 |

18 |

32 |

107 |

95 |

41 |

5~10 |

25 |

20 |

| 76.1 |

2.996 |

75-77 |

18 |

32 |

110.2 |

95 |

41 |

5~10 |

25 |

20 |

| 79.5 |

3.130 |

78-81 |

18 |

32 |

113.6 |

95 |

41 |

5~10 |

25 |

20 |

| 84 |

3.307 |

83-85 |

18 |

32 |

118 |

95 |

41 |

5~10 |

25 |

20 |

| 88.9 |

3.500 |

88-90 |

18 |

32 |

123 |

95 |

41 |

5~10 |

25 |

20 |

| 100.6 |

3.961 |

99-102 |

16 |

32 |

135 |

95 |

41 |

5~10 |

25 |

25 |

| 101.6 |

4.000 |

100-103 |

16 |

32 |

135.7 |

95 |

41 |

5~10 |

25 |

25 |

| 104 |

4.094 |

103-105 |

16 |

32 |

139 |

95 |

41 |

5~10 |

25 |

25 |

| 108 |

4.252 |

106-109 |

16 |

32 |

142 |

95 |

41 |

5~10 |

25 |

25 |

| 114.3 |

4.500 |

113-116 |

16 |

32 |

148.4 |

95 |

41 |

5~10 |

25 |

25 |

| 127 |

5.000 |

126-128 |

16 |

30 |

171 |

110 |

54 |

5~10 |

35 |

40 |

M10×2 |

| 129 |

5.079 |

128-130 |

16 |

25 |

173 |

110 |

54 |

5~15 |

35 |

40 |

| 130.2 |

5.126 |

129-132 |

16 |

25 |

174.3 |

110 |

54 |

5~15 |

35 |

40 |

| 133 |

5.236 |

131-135 |

16 |

25 |

177 |

110 |

54 |

5~15 |

35 |

40 |

| 139.7 |

5.500 |

138-142 |

16 |

25 |

183.8 |

110 |

54 |

5~15 |

35 |

40 |

| 141.3 |

5.563 |

140-143 |

16 |

25 |

185.4 |

110 |

54 |

5~15 |

35 |

40 |

| 154 |

6.063 |

153-156 |

16 |

25 |

196.4 |

110 |

54 |

5~15 |

35 |

40 |

| 159 |

6.260 |

158-161 |

16 |

25 |

203 |

110 |

54 |

5~15 |

35 |

40 |

| 168.3 |

6.626 |

167-170 |

16 |

25 |

209 |

110 |

54 |

5~15 |

35 |

40 |

| 193.7 |

7.626 |

192-196 |

16 |

22 |

235 |

142 |

80 |

15~20 |

40 |

60 |

M12×2 |

| 200 |

7.874 |

198-202 |

10 |

22 |

242 |

142 |

80 |

15~20 |

40 |

60 |

| 204 |

8.031 |

202-206 |

10 |

22 |

252 |

142 |

80 |

15~20 |

40 |

60 |

| 206 |

8.110 |

204-208 |

10 |

22 |

254 |

142 |

80 |

15~20 |

40 |

60 |

| 219.1 |

8.626 |

216-222 |

10 |

22 |

270 |

142 |

80 |

15~20 |

40 |

60 |

| 244.5 |

9.626 |

242-247 |

10 |

22 |

295 |

142 |

80 |

15~20 |

40 |

60 |

| 250 |

9.843 |

247-253 |

10 |

20 |

299 |

142 |

80 |

15~20 |

40 |

60 |

| 254 |

10.000 |

251-257 |

10 |

20 |

302 |

142 |

80 |

15~20 |

40 |

60 |

| 256 |

10.079 |

253-259 |

10 |

20 |

304 |

142 |

80 |

15~20 |

40 |

60 |

| 267 |

10.512 |

264-270 |

10 |

20 |

317 |

142 |

80 |

15~20 |

40 |

60 |

| 273 |

10.748 |

270-276 |

10 |

20 |

323 |

142 |

80 |

15~20 |

40 |

60 |

GRIP-GF Material Selection

| Material Components |

V1 |

V2 |

V3 |

V4 |

V5 |

V6 |

| Casing |

AISI 304 |

AISI 316L |

AISI 316TI |

AISI 316L |

AISI 316TI |

|

| Bolts |

AISI 304 |

AISI 316L |

AISI 316L |

AISI 304 |

AISI 304 |

|

| Bars |

AISI 304 |

AISI 316L |

AISI 316L |

AISI 304 |

AISI 304 |

|

| Anchoring ring |

AISI 301 |

AISI 301 |

AISI 301 |

AISI 301 |

AISI 301 |

|

| Strip insert (optional) |

AISI 301 |

AISI 301 |

AISI 301 |

AISI 301 |

AISI 301 |

|

Material of rubber gasket

| Material of seal |

Media |

Temperature range |

| EPDM |

All quality of waters,waste water, air, solids and chemical products |

-30℃ up to+120℃ |

| NBR |

Water,gas, oil, fuel and other hydrocanbons |

-30℃upto+120℃ |

| MVQ |

High temperature liquid, oxygen, ozone, water and so on |

-70℃ up to+260℃ |

| FPM/FKM |

Ozone, oxygen, acids,gas, oil and fuel (only with strip insert) |

95℃up to+300℃ |

The GRIP-GF represents the ultimate in high security fire protected mechanical pipe couplings.

The advantage of grip fire proof type coupling

1. No thick smoke and smell after burning rubber when fire, will not be choking.

2. Not only keep coupling and pipe well, also protect personnel from rubber smoke dust and smell.

Application:

Shipbuilding industry

Tunneling

Fire hose pipelines

Engine development